Direct throw broom sweepers are prevalent in Australian factories. The mechanism involves a rotating broom that flicks debris into a front-mounted hopper. Once sweeping is complete, a trap door ramp seals the load, allowing it to be lifted and emptied over a bin.

Popular Brands

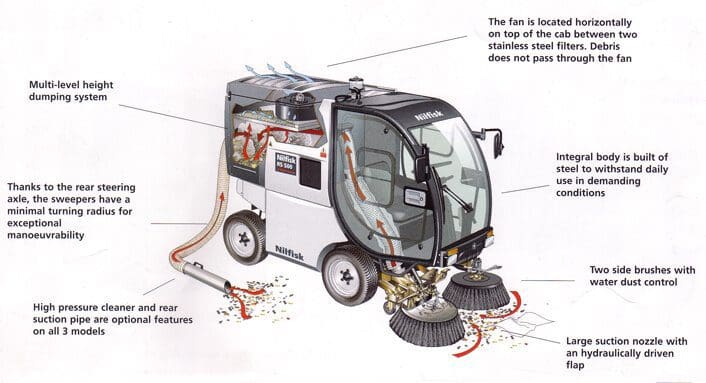

Popular brands offering this type include Fimap, American Lincoln, Tennant and Nilfisk.

Features

- Air Filtration: Larger models come with hydraulic air fans and panel filters to clear disturbed air. In environments with consistently heavy dust, electric vibrators assist in clearing blockages.

- Efficiency: Highly effective at gathering both small and large debris.

- Ease of Service: Generally easier to service, especially if they use panel filters.

How They Work

Similar to direct throw sweepers but with a different hopper placement—right at the rear of the broom. This design allows for litter to be thrown over the broom into the hopper.

Benefits

- Better Visibility: A more forward seating position for the operator provides better visibility.

- Greater Hopper Volume: Designed to collect more waste before needing to be emptied.

Limitations

- Efficiency: Less efficient at collecting larger, rougher debris.

- Durability: The hoppers can be more susceptible to damage, given the industry’s familiarity primarily with direct throw models.

Filtration

- Panel or Bag Filters: Dust is typically filtered through either a panel filter or a bag type, each with its own set of advantages and disadvantages.

Which Sweeper Machine to Choose?

Choosing between the two largely depends on your specific needs, including the type of debris you’ll be collecting and the layout of your facility. Both options have their merits and drawbacks, so it’s vital to consider what’s most crucial for your operation.

Feel free to consult with us to find the best match for your needs. Our extensive knowledge in factory cleaning equipment can help guide you through the selection process.